28 Oct 2019

23 Best Aluminum Welding Wires

Hobart Handler 210 MVP MIG Welder with H381806-R18 1-Pound ER4043 Aluminum Welding Wire, 0.030-Inch - Dual-voltage (115v/230v) with mvp plug makes the unit easy to find a place to plug it in. It can be used to weld various grades of aluminum. 7 voltage settings which help fine tune for precision welding. Its bright weld finish makes it a popular choice of welders. Welds 24 ga to 3/8 in steel in a single pass. A general-purpose type aluminum welding wire.

ER5356 – MIG Aluminum Welding Wire – 1 Lb x 0.035″ - One of the most commonly used aluminum welding alloy. 1 lb spool. Extremely resistant to corrosion and resistant to sea water suitable for subsequent anodization. Shielding gas 100% argon, argon / helium mixtures. This is one of the most commonly used aluminum welding alloy.

Imperial 89091 Aluminum Welding Wire, 0.035 - Highlights excellent weldability with or without shielding gas weld-it mig wires have minimal spatter and easy slag clean up er 4043 wire.

ER4043 – MIG Aluminum Welding Wire – 1 Lb x 0.045″ - 13 0. 6 45-75 shielding gas 100% argon, argon / helium mixtures the above parameters are for reference purpose and depend on diverse factors. Uses materials alsimg, almgsi. 035″ 450-750 70-185 15-27 1. 0003 typical test result 0. 8 0. 0 0. 65-1. For welding 6xxx alloys, and most casting alloys, automotive components such as frame and drive shafts, bicycle frames chemical composition (%) chemical composition al si fe cu mn requirement balance 4. Untreated low strength values. Er4043, wire, mig (gmaw), aluminum aws a5. 25 25-30 0. 25 35-45 1/16″ 250-450 170-300 24-30 3. 2 0. 25 30-35 0. Resistant to hot cracks. 045″ 330-500 125-260 20-29 1. 0-4. 03 0. Main areas of use are welds on cast aluminum. 12 0. 3 0. 05 0. 05 typical test result balance 5. 01 chemical composition mg zn ti be requirement 0. 1 0. 01 0. Run tests, evaluate and set your welding parameters before starting the welding job. 10 welding positions all, except vertical down introduction mig solid wire electrode with aluminum 5% silicon for welding heat-treatable base alloys and more specifically, 6xxx series alloys. 5-6. 002 0. 007 0. Not recommended for materials to be anodized. 0-4. 8-6. 030″ 480-626 60-175 15-24 0. 0002 welding parameters (dc+) diameter wfs (ipm) amps volts (lb/100 ft) argon (cfh) 0.

Hobart H383808-R18 1-Pound ER5356 Aluminum Welding Wire, 0.035-Inch - ). Product type welding wire, wire size (in. 035, wire material aluminum alloy, weight (lbs. ) 1, compatible with mig welders, welding processes general purpose. Hobart er5356 aluminum welding wire is a general-purpose type aluminum alloy, which is typically chosen for its relatively high shear strength.

ER4043 – MIG Aluminum Welding Wire – 1 Lb x 0.045″ (4 SPOOLS) - 5-6. Er4043, wire, mig (gmaw), aluminum aws a5. 05 typical test result balance 5. 25 35-45 1/16″ 250-450 170-300 24-30 3. 05 0. For welding 6xxx alloys, and most casting alloys, automotive components such as frame and drive shafts, bicycle frames chemical composition (%) chemical composition al si fe cu mn requirement balance 4. Resistant to hot cracks. 25 30-35 0. 8-6. 2 0. 01 chemical composition mg zn ti be requirement 0. 65-1. 035″ 450-750 70-185 15-27 1. 0002 welding parameters (dc+) diameter wfs (ipm) amps volts (lb/100 ft) argon (cfh) 0. 6 45-75 shielding gas 100% argon, argon / helium mixtures the above parameters are for reference purpose and depend on diverse factors. 0 0. Main areas of use are welds on cast aluminum. 3 0. 002 0. 10 welding positions all, except vertical down introduction mig solid wire electrode with aluminum 5% silicon for welding heat-treatable base alloys and more specifically, 6xxx series alloys. 12 0. Not recommended for materials to be anodized. 1 0. 0-4. 13 0. 25 25-30 0. Run tests, evaluate and set your welding parameters before starting the welding job. 030″ 480-626 60-175 15-24 0. 0003 typical test result 0. 007 0. Untreated low strength values. 0-4. 8 0. 045″ 330-500 125-260 20-29 1. 03 0. Uses materials alsimg, almgsi. 01 0.

Blue Demon ER1100 X .035 X 16# Spool aluminum welding wire - Has good welding characteristics and is used as a filler alloy for welding. Applications include heat exchangers, food handling equipment, rivets, tie wire and metallizing. Has bright finishes obtained by anodizing.

ER4043 – MIG Aluminum Welding Wire – 1 Lb x 0.045″ (2 SPOOLS) - 045″ 330-500 125-260 20-29 1. Uses materials alsimg, almgsi. 25 25-30 0. 030″ 480-626 60-175 15-24 0. 25 30-35 0. 5-6. 0-4. 0-4. 8-6. Run tests, evaluate and set your welding parameters before starting the welding job. Not recommended for materials to be anodized. 05 typical test result balance 5. 0002 welding parameters (dc+) diameter wfs (ipm) amps volts (lb/100 ft) argon (cfh) 0. 05 0. 8 0. 01 chemical composition mg zn ti be requirement 0. 007 0. Er4043, wire, mig (gmaw), aluminum aws a5. 0 0. 65-1. 002 0. 6 45-75 shielding gas 100% argon, argon / helium mixtures the above parameters are for reference purpose and depend on diverse factors. 0003 typical test result 0. 12 0. Resistant to hot cracks. Main areas of use are welds on cast aluminum. 25 35-45 1/16″ 250-450 170-300 24-30 3. 01 0. 1 0. Untreated low strength values. 03 0. 3 0. For welding 6xxx alloys, and most casting alloys, automotive components such as frame and drive shafts, bicycle frames chemical composition (%) chemical composition al si fe cu mn requirement balance 4. 035″ 450-750 70-185 15-27 1. 2 0. 13 0. 10 welding positions all, except vertical down introduction mig solid wire electrode with aluminum 5% silicon for welding heat-treatable base alloys and more specifically, 6xxx series alloys.

Weldflame ER4043 1-Pound General Purpose Aluminum Welding Wire 0.035 Inch - A general-purpose type aluminum welding wire. Its bright weld finish makes it a popular choice of welders. 1-lb, er4043 mig welding wire wrapped in moisture-resistant plastic film. A popular choice due to its versatility.

Lot 2 Hobart ER 4043 ALUMINUM MIG Welding Wire .035 X 1 LB SPOOL GENERAL PURPOSE - Bright weld finish makes it a popular choice of welders. Lot 2 hobart er 4043 aluminum mig welding wire. 035 x 1 lb spool general purpose product summary hobart mig welding wire is a general purpose type aluminum welding wire that contains silicon additives which result in improved fluidity (wetting action) of the weld pool and also produces a weld less sensitive to cracking. Can be used to weld various grades of aluminum.

ER5356 – MIG Aluminum Welding Wire – 1 Lb x 0.030″ (2 SPOOLS) - Extremely resistant to corrosion and resistant to sea water suitable for subsequent anodization. This is one of the most commonly used aluminum welding alloy. One of the most commonly used aluminum welding alloy. Shielding gas 100% argon, argon / helium mixtures. Two spools of 1 lb each.

1 spool ER4043 .030″ 1lb Aluminum MiG welding wire - Contains 5% magnesium and the weld deposits show excellent resistance to corrosion and salt water. Weldtool. 030″ (. The product for sale is a spools of new fema. If you want more information on us or fema and our products contact us. Other areas please e mail shipping destination for cost. 030 wire is particularly good for general purpose thickness’ of aluminum welding with 115v and 230v mig units and spool on gun mig machines. Sold by the welding specialist. 1lb is ideal and excellent for reducing wastage for most specific job projects and keeps initial purchase price low. 1lb is light and therefore ideal for economy yet practicality on portable and spool on gun mig machines. General purpose, auto body repair, fabrication, maintenance, farm and or agricultural or shop welding. Free shipping within the continental usa. Best results are when used with 100 argon mig. Er5356 mig welding wire is a good general purpose welding wire for aluminum. Precision wound wire, allows smoother wire flow than random spooled wire. 45kg), er4043 high quality aluminum general purpose precision wound mig welding wire. It contains 5% magnesium and offers excellent corrosion resistant properties. Standard 4″ spool size with standard 5/8″ spindle hole opening. Precision wound wire produces smoother welding wire flow. 030 wire is particularly good for mig welding on both thin and thicker material. Why you should buy it a high quality er5356 aluminum mig welding wire. $043 contains 5% silicone making welding easier and with better crack resistant properties. Features include. 8mm), 1lb (. Excellent general purpose wire for the welding of most aluminums.

ER5356 – MIG Aluminum Welding Wire – 1 Lb x 0.045″ (4 SPOOLS) - This is one of the most commonly used aluminum welding alloy. Four spools of 1 lb each. One of the most commonly used aluminum welding alloy. Shielding gas 100% argon, argon / helium mixtures. Extremely resistant to corrosion and resistant to sea water suitable for subsequent anodization.

LOT 4 ALUMINUM MIG Welding Wire Hobart ER 4043 .035 X 1 LB SPOOL GENERAL PURPOSE - Bright weld finish makes it a popular choice of welders. Can be used to weld various grades of aluminum. 035 x 1 lb spool general purpose product summary hobart mig welding wire is a general purpose type aluminum welding wire that contains silicon additives which result in improved fluidity (wetting action) of the weld pool and also produces a weld less sensitive to cracking. Lot 4 hobart er 4043 aluminum mig welding wire.

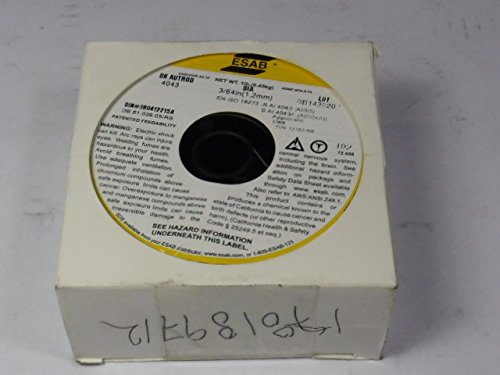

Esab 180412215A MIG Aluminum Welding Wire 1.2mm - Shielding gas 100% argon, argon / helium mixtures. Uses automotive components such as frame and drive shafts, bicycle frames. 1 lb spool. This item is new, including original packaging. For welding heat-treatable base alloys and more specifically, 6xxx series alloys.

ER4043 – MIG Aluminum Welding Wire – 1 Lb x 0.035″ (2 SPOOLS) - 030″ 480-626 60-175 15-24 0. Not recommended for materials to be anodized. Er4043, wire, mig (gmaw), aluminum aws a5. 2 0. 03 0. 0-4. Main areas of use are welds on cast aluminum. 5-6. 25 35-45 1/16″ 250-450 170-300 24-30 3. 007 0. For welding 6xxx alloys, and most casting alloys, automotive components such as frame and drive shafts, bicycle frames chemical composition (%) chemical composition al si fe cu mn requirement balance 4. 3 0. 25 30-35 0. 0-4. 002 0. 01 0. 6 45-75 shielding gas 100% argon, argon / helium mixtures the above parameters are for reference purpose and depend on diverse factors. Run tests, evaluate and set your welding parameters before starting the welding job. Resistant to hot cracks. Untreated low strength values. 13 0. 05 0. 25 25-30 0. 035″ 450-750 70-185 15-27 1. 01 chemical composition mg zn ti be requirement 0. 0003 typical test result 0. 045″ 330-500 125-260 20-29 1. 12 0. Uses materials alsimg, almgsi. 0 0. 0002 welding parameters (dc+) diameter wfs (ipm) amps volts (lb/100 ft) argon (cfh) 0. 10 welding positions all, except vertical down introduction mig solid wire electrode with aluminum 5% silicon for welding heat-treatable base alloys and more specifically, 6xxx series alloys. 65-1. 1 0. 8-6. 05 typical test result balance 5. 8 0.

ALUMINUM MIG Welding Wire LOT 3 Hobart ER 4043 .035 X 1 LB SPOOL GENERAL PURPOSE - Lot 3 hobart er 4043 aluminum mig welding wire. 035 x 1 lb spool general purpose product summary hobart mig welding wire is a general purpose type aluminum welding wire that contains silicon additives which result in improved fluidity (wetting action) of the weld pool and also produces a weld less sensitive to cracking. Bright weld finish makes it a popular choice of welders. Can be used to weld various grades of aluminum.

Aluminum Welding Wire - Safely weld aluminum with specially designed aluminum welding wire welding aluminum is easier than ever with this roll of, visit harbor freight tools for more information.

1 spool ER5356 .030″ 1lb Aluminum MiG welding wire - Standard 4″ spool size with standard 5/8″ spindle hole opening. Best results are when used with 100 argon mig. Free shipping within the continental usa. Sold by the welding specialist. It contains 5% magnesium and offers excellent corrosion resistant properties. 1lb is ideal and excellent for reducing wastage for most specific job projects and keeps initial purchase price low. 030 wire is particularly good for mig welding on both thin and thicker material. Er5356 mig welding wire is a good general purpose welding wire for aluminum. The product for sale is a spools of new fema. 45kg), er5356 high quality aluminum general purpose precision wound mig welding wire. Contains 5% magnesium and the weld deposits show excellent resistance to corrosion and salt water. 1lb is light and therefore ideal for economy yet practicality on portable and spool on gun mig machines. 030 wire is particularly good for general purpose thickness’ of aluminum welding with 115v and 230v mig units and spool on gun mig machines. Other areas please e mail shipping destination for cost. If you want more information on us or fema and our products contact us. Precision wound wire produces smoother welding wire flow. Excellent general purpose wire for the welding of most aluminums. Precision wound wire, allows smoother wire flow than random spooled wire. Features include. 030″ (. 8mm), 1lb (. Why you should buy it a high quality er5356 aluminum mig welding wire. Weldtool. General purpose, auto body repair, fabrication, maintenance, farm and or agricultural or shop welding.

ER4043 – MIG Aluminum Welding Wire – 16 Lb x 0.035″ - Main areas of use are welds on cast aluminum. 0002 welding parameters (dc+) diameter wfs (ipm) amps volts (lb/100 ft) argon (cfh) 0. 10 welding positions all, except vertical down introduction mig solid wire electrode with aluminum 5% silicon for welding heat-treatable base alloys and more specifically, 6xxx series alloys. 03 0. Untreated low strength values. Resistant to hot cracks. Er4043, wire, mig (gmaw), aluminum aws a5. 030″ 480-626 60-175 15-24 0. 035″ 450-750 70-185 15-27 1. 13 0. 007 0. 0003 typical test result 0. Run tests, evaluate and set your welding parameters before starting the welding job. 5-6. 0-4. 8 0. 0 0. 01 0. For welding 6xxx alloys, and most casting alloys, automotive components such as frame and drive shafts, bicycle frames chemical composition (%) chemical composition al si fe cu mn requirement balance 4. 045″ 330-500 125-260 20-29 1. Uses materials alsimg, almgsi. 05 0. 25 25-30 0. 8-6. 25 35-45 1/16″ 250-450 170-300 24-30 3. 12 0. 3 0. 6 45-75 shielding gas 100% argon, argon / helium mixtures the above parameters are for reference purpose and depend on diverse factors. 25 30-35 0. 05 typical test result balance 5. Not recommended for materials to be anodized. 01 chemical composition mg zn ti be requirement 0. 002 0. 1 0. 0-4. 2 0. 65-1.

New Forney 42293 Aluminum Welding Wire 1 Lb Spool .030 Mig Welder 8915589 - Features 5% magnesium content and a bright finish. 8 degrees c) and provides less ‘bird-nesting’ on push-type mig welders. 030 wt lb 1. Description du français soudure fils alum mig 0030 po. Tensile strength (psi) 63000. Welding suppliesforneyfactory sealed newgreat sale pricewe will also combine shipping and ship each additonal item for 2. 1 lbdescripción español soldadora con cable mig de 076 cm por 53592 grer5356, aluminum dia in . Recommended polarity dcep reverse. Light grey color coding on label. It flows freely at 1180 degrees f (637. Applications include diesel engine bases truck frames cargo tanks and gun mount bases. Required shielding gas argon. 00 shipping.

ER5356 – MIG Aluminum Welding Wire – 1 Lb x 0.030″ (4 SPOOLS) - Four spools of 1 lb each. One of the most commonly used aluminum welding alloy. Extremely resistant to corrosion and resistant to sea water suitable for subsequent anodization. Shielding gas 100% argon, argon / helium mixtures. This is one of the most commonly used aluminum welding alloy.

ER4043 – MIG Aluminum Welding Wire – 1 Lb x 0.035″ - Not recommended for materials to be anodized. Resistant to hot cracks. 6 45-75 shielding gas 100% argon, argon / helium mixtures the above parameters are for reference purpose and depend on diverse factors. 035″ 450-750 70-185 15-27 1. 5-6. 1 0. 12 0. Main areas of use are welds on cast aluminum. 65-1. 03 0. 0-4. 0002 welding parameters (dc+) diameter wfs (ipm) amps volts (lb/100 ft) argon (cfh) 0. 01 chemical composition mg zn ti be requirement 0. 8 0. 0003 typical test result 0. 0 0. Er4043, wire, mig (gmaw), aluminum aws a5. 05 0. 030″ 480-626 60-175 15-24 0. 045″ 330-500 125-260 20-29 1. 25 35-45 1/16″ 250-450 170-300 24-30 3. 2 0. 25 25-30 0. 01 0. 0-4. 10 welding positions all, except vertical down introduction mig solid wire electrode with aluminum 5% silicon for welding heat-treatable base alloys and more specifically, 6xxx series alloys. 05 typical test result balance 5. 25 30-35 0. Uses materials alsimg, almgsi. 3 0. Untreated low strength values. Run tests, evaluate and set your welding parameters before starting the welding job. 002 0. For welding 6xxx alloys, and most casting alloys, automotive components such as frame and drive shafts, bicycle frames chemical composition (%) chemical composition al si fe cu mn requirement balance 4. 007 0. 8-6. 13 0.

We are a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.